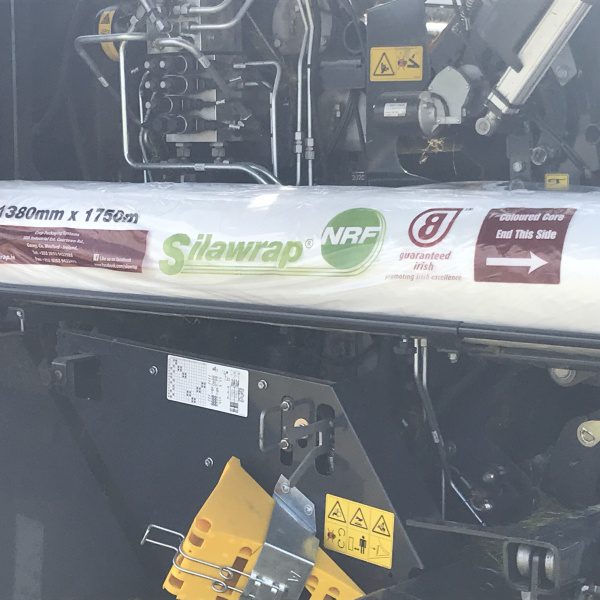

Silawrap Net Replacement Film (25 Rolls)

Silawrap NRF adds extra layers of film tight around the barrel of the bale. This improves the Oxygen Barrier. The extra layers lead to better bale storage and improved quality silage. This gives better animal performance leading to increased profits.

Price is per pallet with 25 rolls a pallet £155 a roll

Due to being a fast moving product please call to check stock before ordering.

£3,875.00

Description

NET REPLACEMENT FILM

Using plastic film instead of net to hold a bale together is the latest significant

development in the production of baled silage. Silawrap NRF works on suitably

engineered combination baler/wrapper units like the Mc Hale Fusion 3 plus, Goweil, Pottinger,

Orkel, Flexus and Krone. Crop Packaging Systems have combined a mix of resins with

our manufacturing expertise to develop Silawrap NRF. Silawrap NRF has been used

in Ireland, the U.K., France, Norway, Austria, Switzerland, Finland, Sweden and New

Zealand. Whole crop barley, alfalfa, lucerne, maize and grass have all been baled

successfully with Silawrap NRF. More importantly for our climate a wide range of grass

has been baled, from leafy and wet to stemy and dry. Silawrap NRF is a different product

to Silawrap bale wrapping film. It is not as elastic as it is required to hold the bale

together. In fact Silawrap NRF holds bales tighter than net thus reducing air ingress

after the bale is released from the baler. This improves silage quality.

HOW IT WORKS

Silawrap NRF is stretched onto the bale. Its elasticity and strength properties hold the

bale together. This is vital to ensure correct wrapping. The film also helps to seal in

the goodness of the forage and keep out air. This leads to improved feed quality, better

storage and increased animal production.

SILAGE QUALITY:

Silawrap NRF adds extra film to the barrel of the bale. The Oxygen barrier is improved.

Silage stores better. This leads to better quality silage, improved animal production and

increased farm profits.

REDUCES MOULD:

Mould reduces silage quality. Extra film on the barrel of the bale reduces vermin and

handler damage. As a result quality is improved. Milk, beef or lamb production increas-

es per bale leading to more profitable farming.

LABOUR SAVING:

No need to separate net and film when opening bales. This reduces feeding time, makes

waste disposal easier and reduces costs.

BETTER SHAPED BALE:

Silawrap NRF compresses the bale tighter than net. This keeps the bale in better shape.

TIPS TO ENSURE BEST USE OF SILAWRAP NRF…

• Set the stretch ratio to Max 18% depending on wrapping conditions.

• Centre the roll accuratly when loading into the baler. This will insure even coverage on

the bale and will enable the film to wrap over the side of the bale.

• Do not try to use Silawrap NRF on an unmodified machine

• Setting the machine and stretch % properly will ensure the film goes over the side of

the bale by 3 to 4 cm.

• Silawrap NRF has left, right roll markings to show the opperator which way to load

the roll into the baler. Keep Silawrap NRF in it’s packaging to avoid roll damage until

time of use.

• Apply a minimum of 3.5 turns of Silawrap NRF to the bale. This ensures a minimum of

2 layers of NRF on all of the bale

Related products

-

- Out of Stock

- WRAP & TWINE

Tamanet Bale Wrap

- £237.50

- Buy Now

-

-

- ATV EQUIPMENT, ATV HARROWS, HARROWS/AERATORS, New Farming Machinery

Trailed Chain Harrows

- £300.00 – £750.00

- Buy Now This product has multiple variants. The options may be chosen on the product page